What Is a Mezzanine System?

A mezzanine system is an intermediate floor built within an existing warehouse structure. Unlike permanent construction, mezzanines are semi-permanent installations that can be customized, expanded, or even relocated depending on business needs. These systems are supported by steel columns and can be designed to handle different weight capacities, making them suitable for storage, offices, picking areas, or even production zones. By going vertical, you effectively multiply your floor space without expanding your warehouse footprint. According to Occupational Safety and Health Administration (OSHA), this systems must also comply with strict safety guidelines, ensuring secure operations for workers while maximizing space efficiency.

Key Benefits of Installing a Mezzanine System

1. Maximizes Vertical Space

Most warehouses have unused vertical clearance. A mezzanine takes advantage of this wasted space, turning it into functional square footage. For facilities with high ceilings, this can literally double the operational area.2. Cost-Efficient Expansion

Building a new facility or relocating is expensive and disruptive. This system provides a far more affordable solution—with the ability to expand capacity in weeks instead of months or years.3. Flexibility and Scalability

Mezzanines can be designed for multiple applications: Additional storage for pallets and inventory Office space for administrative staff inside the warehouse Picking and packing areas closer to fulfillment zones Specialized operations like light manufacturing Best of all, mezzanine systems can be reconfigured as your business grows.4. Improved Workflow Efficiency

By segmenting operations—such as creating a second-level picking area above storage—you can streamline logistics processes. This reduces travel time for workers and improves overall warehouse efficiency.5. Compliance and Safety Features

Modern mezzanines are designed with safety in mind, including guardrails, staircases, and load-bearing specifications. OSHA-compliant systems reduce liability while ensuring worker safety.Types of Mezzanine Systems

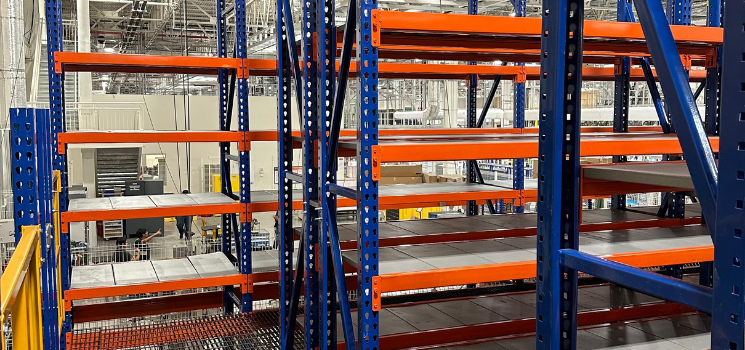

Not all mezzanines are the same. Depending on your warehouse needs, you can choose from several types:- Rack-Supported Mezzanines: Built on top of racking systems, ideal for warehouses already using pallet racks.

- Shelving-Supported Mezzanines: Perfect for smaller items, allowing dense storage solutions.

- Structural Mezzanines: Independent freestanding structures offering maximum versatility.

Mezzanine Systems vs. Alternatives

Some businesses consider alternatives like drive-in racking or high-density storage systems to maximize capacity. While effective, these options typically optimize horizontal space, whereas mezzanines allow you to go vertical without reducing accessibility. For warehouses struggling with both inventory growth and workflow needs, mezzanines provide a balanced solution—storage and operations in one structure.

Real-World Applications

- E-commerce Distribution Centers: Handle seasonal spikes by adding mezzanine-supported picking areas.

- Manufacturing Facilities: Create production zones above raw material storage.

- 3PL Providers: Scale space quickly without signing new long-term leases.

- Cold Storage Warehouses: Expand storage while maintaining temperature-controlled zones.

Conclusion

Mezzanine systems represent one of the smartest investments for large-scale storage optimization. They provide immediate space expansion, improve workflow, and offer flexibility for future growth—all at a fraction of the cost of relocation or new construction.At RackUSA, we specialize in designing mezzanine systems that align with your exact operational needs. Whether you’re looking to double your warehouse space, streamline processes, or prepare for future growth, our team is ready to deliver tailored solutions.